The one part of note because of its expense is the bellows also called the

motor. It is the large round "bowl shaped" object on the back of the clock

The current replacement cost that I charge is $900.00 (if needed and price subject to change).

A refill of your old bellows costs $300.00 plus shipping and can be done about 80% of the

time and keeps the clock 100% original.

Many on the Internet have advised people to place the entire clock in a

freezer for a few minutes. Please don't ever do this because that

exposure will leave either water vapors or droplets on everything and will

eventually rust all the moving steel parts. Besides this "method" tells you

nothing if the mainspring is fully wound, which is the case in most Atmos clocks.

The bellows winds the mainspring, or more accurately, the bellows keeps the

mainspring wound and can wind the spring but that would take months. Before you

test the clock make sure that the clock has power by letting the clock be exposed

to some temperature fluctuations (4 degrees Fahrenheit or more) over

the next few weeks. This will start to wind the mainspring if needed.

The bellows have an upper and lower temperature limits and these

are 86°F and 46.4°F respectively. If the temperature is constantly

outside these limits, the bellows will not wind the mainspring.

These temperature changes will cause the bellows to expand

and contract therefore winding the mainspring. The bellows power

is passed on to the mainspring via the brass chain that you see at

the roughly center of the movement. When the bellows is good it

contains sufficient gas (ethylene chloride I was told) to exert

pressure on the chain (indirectly).

The following check MUST be done at 68 degrees Fahrenheit.

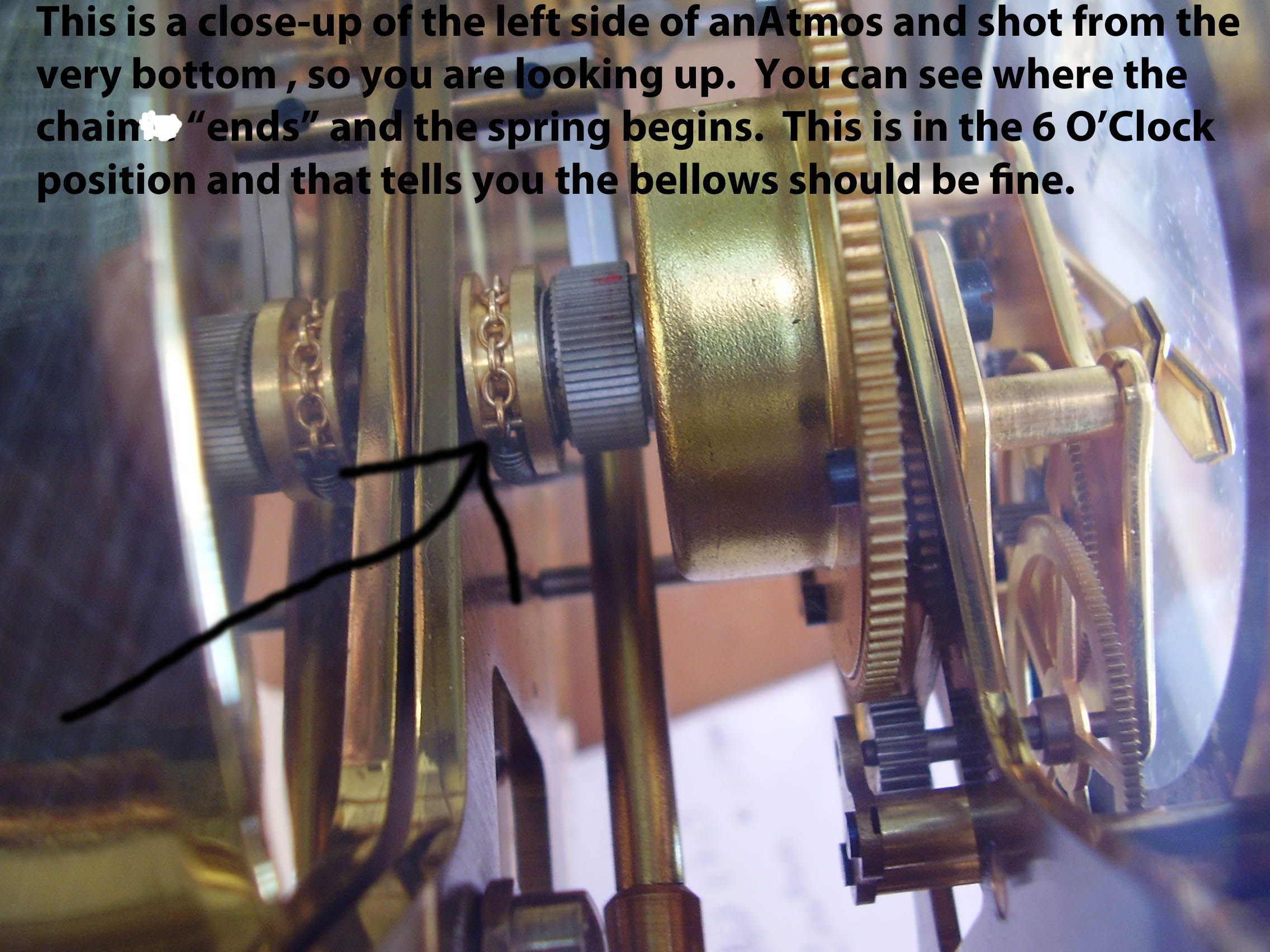

The chain comes out of the bellows chamber (the large round bowl

like piece) and makes a left turn (as you face the clock) around

a pulley. It continues to travel around to a second pulley. This second

pulley is the one which is actually attached to the mainspring arbor

and the chain end makes a counter-clockwise wrap around this

second pulley. The result should be that the chain end is now

underneath the second pulley. If the chain end is resting on top of

that second pulley then the bellows is flat (or you live in a freezer)

and therefore needs replacing.

Anywhere in between the bottom position (roughly 6 O'clock)

to the top position (roughly 12 O'clock), the bellows has lost

some gas and it MAY have enough gas to continue the wind the mainspring.

The closer the chain end is to the bottom position the better.

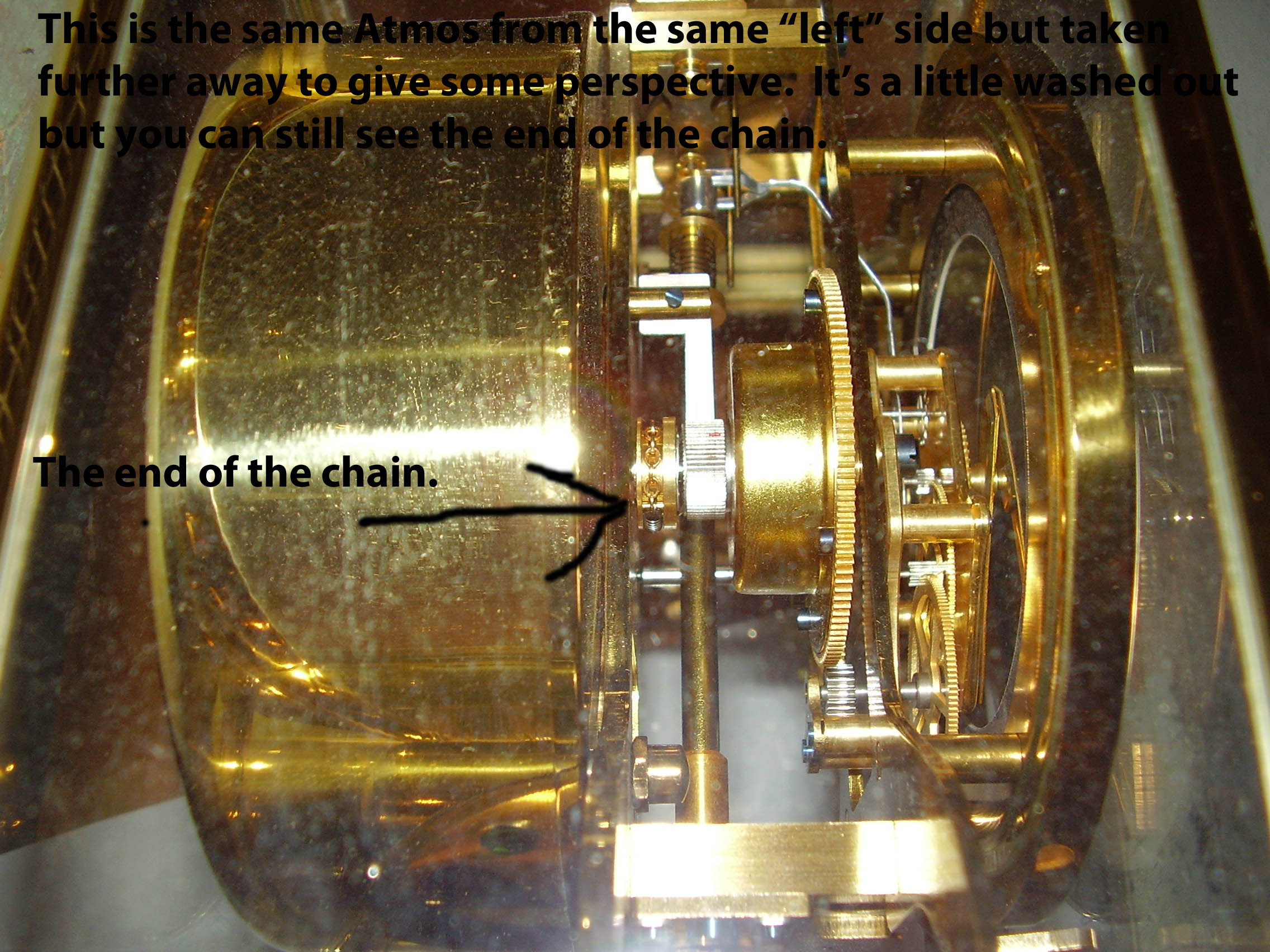

Here are two pictures displaying a good bellows based on the position

of the chain. The first is taken to display most of the Atmos' "left"

side and the second is a much more close shot of the same Atmos.

The best way to see if the bellows is good is to take the

bellows chamber off the clock. The chamber is held in usually by

two or four brass nuts. I use a 5/16" closed end wrench to remove

these nuts and they are actually 8mm but either will work fine. A

word of warning here because the above mentioned chain is

attached to a fairly strong spring and that spring will "push" the

bellows chamber away from the movement as you remove these

nuts. On the caliber (model) # 540 the bellows chamber is removed

by exerting a counter-clockwise (bayonet fitting) turning pressure with

your hands and be sure to turn the "inner" part of the drum. In other

words turn as close to the frame as possible.

Once the bellows chamber is removed you measure the depth

from the top lip of the bellows chamber opening down to the top of the

actual bellows. This will be obvious once you have the bellows chamber

off the movement. Do NOT remove the bellows itself for this measurement.

At room temperature the depth should be between 22 to 26mm,

if the depth is 26 to 32mm then the bellows is questionable but should

still provide years of service. Anything over 32mm the bellows must be

replaced because that means that there is no gas contained within

the bellows.

The "real" check is how many winds (turns) on the mainspring.

If the mainspring has 4 or more turns then the bellows are doing their job

regardless of their depth.

For the caliber 540, the depth should be between 20 to 24mm,

and 24 to 30 for a questionable bellows. Anything over 30mm should

be replaced.

Again the check, for the 540, is at disassembly and the turns

on the winding wheel or ratchet wheel (both turn at the same rate) and

not the mainspring. The winding wheel should have at least 3 turns,

which translates into 9 turns on the watch like mainspring inside the barrel.

As a final check to make sure the bellows is indeed okay, you

can place the entire bellows chamber in the freezer for about three to

five minutes. If the bellows is good it will collapse to almost flat

which would give you a measurement of about 40 to 44mm. Or you can

place a piece of ice on top of the bellows and is should begin

collapsing within about 15 seconds.

In either case above do NOT allow the bellows to be exposed

to the cold any longer five minutes because you can damage this very

expensive piece.

Return to Index

Replacement

The bellows or "motor" contains the following:

1) Motor knobs (either two or four nuts); Part # 3519.

2) Motor protection plate; Part # 3546.

3) Coil spring (70mm); Part # 3547

4) Metal (brass) drum; Part # 3580

5) Bellows; Part # 3581

6) Drum cover; Part # 3582

For schematics with the part numbers, please see:

Part Schematics

In order to replace the old bellows for a new one you first

remove the entire "motor" or bellows chamber (see above). There

are either two or four brass nuts which hold the motor to the back

of the frame plate. I use a 5/16" closed end wrench to remove these

nuts. A word of warning here because the above mentioned chain

is attached to a fairly strong spring and that spring will "push" the

bellows chamber away from the movement as you remove these

nuts. On the caliber (model) # 540 the bellows chamber is removed

by exerting a counter-clockwise (bayonet fitting) turning pressure

with your hands and be sure to turn the "inner" part of the

drum. In other words turn as close to the frame as possible.

To remove the old bellows you must make sure it is fully

compressed. An old bellows with all of its gas leaked away will

measure about 40 mm from the top of the metal drum to the top of

the compressed bellows. Most usually have some gas (ethylene chloride)

remaining. Therefore you must compress the bellows yourself. Some

place the chamber into the refrigerator but I like to use ice cubes.

Usually one ice cube is enough to fully compress the bellows in about

a minute. Once it is compressed, push down on the drum cover

(part # 3582) to loosen any bonds that may have formed on that cover

and the coil spring (part # 3547).

On the caliber 540, once the bellows chamber is removed from

the frame, the bellows casing has a bayonet fixing in which both halves

must be turned in opposite directions, with the back of the drum moving

counter-clockwise. Use an ice cube to collapse the bellows when both

removing and installing.

Once satisfied that the coil spring is "flexible" then push down

on the drum cover and turn it in either direction until the four (4) tabs

are fully exposed from under the four (4) tabs which are located on the

metal drum. Caution should be used because of the tension in the coil

spring. This tension will make the drum and the cover separate rapidly

unless you supply the "containing" force so they do not spring

apart quickly.

The rest should be common sense and you do exactly the

opposite in order to place the new bellows inside the motor starting

with the ice cube.

Return to Index

Suppliers of Atmos Parts

The following is a Web site that describes all of the Atmos parts that

I sell. I sell virtually every part for the LeCoultre Atmos.

Obtaining Atmos Parts

Return to Index

Manual Winding

There are several ways to manually wind the Atmos. By far the

best way is to remove the metal drum (part # 3580) which contains the

bellows (part # 3581). The metal drum, which some incorrectly refer to as the

bellows, is simply removed from the frame in order to access the coil spring.

Once it is removed you will see a coil spring (part # 3494) with a brass chain

(part # 3491) running through the middle and attached to the end of the chain

with an aluminum cap called the spring guide (part # 3493). This is all held

together by a bent steel straight pin called the chain stopper (part # 3492).

In order to wind the mainspring properly you simply become the

bellows. Push the coil spring in toward the movement until it will not

compress any more. Then remove you hand and the coil spring will

try to go back to its original position. This going back to the original

position is the actually winding taking place.

By pushing in the coil spring, the clock "prepares" for the

eventually going back or winding. This is similar to a pocket watch

where one direction actually winds the watch and the opposite direction

allows you to go back to the previous position to wind it again.

The reason I like to use the above method is because the

combination of the coil spring and the bridled mainspring does NOT

allow for over winding, assuming you do not "help" the coil

spring while it springs back and you stop pushing when the coil spring's

extension is slightly less than it did the time before. So once you have

compressed the coil spring and it does not "recoil" back to the

original position, the clock is fully wound.

A fully wound clock should run for about 14 months, with about

7 or 8 of those months having enough power to run accurately. After

that the time keeping tends to deteriorate.

If the Atmos still does not run after manual winding, please be

sure to tell the person you are going to hire to overhaul the clock. The

reason is that a marginal bellows will probably not be refilled if the

repair person counts a "healthy" wind on the mainspring.

If wound properly, either by the bellows or by hand

(removing the bellows and pushing the coil spring), which was

described above, then the amount of running time totally depends

on the caliber.

All of these will vary by as much as 4 months but a

caliber 540 will run anywhere from 10 months to 14 months.

A caliber 528/526 will run anywhere from 14 to 16 months and

a caliber 519 and the Atmos II will run anywhere from 15 months

to 2 years.

All of this has to do with the quality and length of

the mainspring. And of course the actual condition of the

movement and frame will change these numbers.

Some choose to wind by turning the chain and spring pulley

(part # 3486). That method is not controllable and you can wind

it too little or too much.

Too little will not hurt anything but too much and

then the clock can have too much power and the balance may

over swing causing the clock to run fast because the roller

will hit the fork on the opposite side and that will limit

the "natural" swing. The general clock terms this is called

over swing.

Another danger of winding this way is that the "stopping

pin" that secures the chain to the "chain stopper", which is the

cap of the coil spring, may become dislodged and the chain will

eventually lose its tension and if the bellows still has some

gas left, then there is no way it will wind the clock.

So please don't be lazy and try to wind by pushing the chain and spring

pulley. I'm mentioning this because some on the Internet advise winding this

way and it's an accident waiting to happen.

Return to Index

Refilling Atmos Bellows

If you want the bellows refilled as a stand alone service, then

the cost is $470.00. That includes return shipping (in the U.S.) and

you will have to remove the spent bellows and sent it to me and

reinstall the refilled bellows.

Refilled bellows carry a 2-year warranty. It's about 4 weeks from the

time I receive your check made out to Mike Murray for $470.00 in the US.

The shipping charge is $20.00 to the US, $45.00 to Canada and

$65.00 to the rest of the world, which includes insurance. For one

week shipping to the rest of the world, you may add $80.00 to the

total of the order because the $65.00 option takes about 2 weeks.

The final price outside North America is either $515.00 or $530.00

depending on your shipping choice.

Please be aware that I do not perform the service myself and

send out the bellows for refilling. Therefore, you must allow

about six weeks for the service and the possibility that the refill

failed.

If you do not have the old bellows, then I can supply a bellows

usually manufactured within a few years of your serial #. That adds

$150.00 to the $450.00 mentioned above.

You must be aware that there is a 20% failure on refilling used

bellows. Therefore, I cannot guarantee that your bellows refill will

be successful. I can, however, have one of my old stock bellows refilled

in case of failure and that adds $150.00 to the refilling charge (see below).

If the procedure fails, then I'll return your original bellows

at no charge, assuming that you sent just the bellows for refilling or

take a spend bellows from my inventory that is close to the date of

your original bellows (usually within a year) and charge $150.00 extra

for a total of $620.00 and that includes the used bellows from my

inventory.

If you sent the entire clock as part of an overhaul, then I will

install either a new bellows at an extra cost of $900.00 (price subject to change)

or use another refilled bellows that is close to the date of your original bellows

(usually within a year) for the an extra $150.00 for a total cost of $600.00.

I would like payment by money order, certified check, personal check,

business check, or through Pay Pal or Square, which is the only way I take

credit cards. I do prefer a check over a credit card because Pay Pal and Square

take 3%. I only take credit cards if you are in the USA or Canada.

The 3% is added to the total bill if you use a credit card.

With either Pay Pal or Square, I will send an invoice to your E-mail

address. Here you are dealing directly with either service and not me

and you do not have to be a member of either.

All of the added fees are exactly what either service charges me

for taking your credit card.

Return to Index

Replacing Soldered Bellows

The best way to see if the bellows is good is to take the

bellows chamber off the clock. The chamber is held in usually by

two or four brass nuts. I use a 5/16" closed end wrench to remove

these nuts and they are actually 8mm but either will work fine. A

word of warning here because the above mentioned chain is

attached to a fairly strong spring and that spring will "push" the

bellows chamber away from the movement as you remove these

nuts. On the caliber (model) # 540 the bellows chamber is removed

by exerting a counter-clockwise (bayonet fitting) turning pressure with

your hands and be sure to turn the "inner" part of the drum. In other

words turn as close to the frame as possible.

Once the bellows chamber is removed you measure the depth

from the top lip of the bellows chamber opening down to the top of the

actual bellows. This will be obvious once you have the bellows chamber

off the movement. Do NOT remove the bellows itself for this measurement.

At room temperature the depth should be between 22 to 26mm,

if the depth is 26 to 32mm then the bellows is questionable but should

still provide years of service. Anything over 32mm the bellows must be

replaced because that means that there is no gas contained within

the bellows.

The "real" check is how many winds (turns) on the mainspring.

If the mainspring has 4 or more turns then the bellows are doing their job

regardless of their depth.

For the caliber 540, the depth should be between 20 to 24mm,

and 24 to 30 for a questionable bellows. Anything over 30mm should

be replaced.

Again the check, for the 540, is at disassembly and the turns

on the winding wheel or ratchet wheel (both turn at the same rate) and

not the mainspring. The winding wheel should have at least 3 turns,

which translates into 9 turns on the watch like mainspring inside the barrel.

As a final check to make sure the bellows is indeed okay, you

can place the entire bellows chamber in the freezer for about three to

five minutes. If the bellows is good it will collapse to almost flat

which would give you a measurement of about 40 to 44mm. Or you can

place a piece of ice on top of the bellows and is should begin

collapsing within about 15 seconds.

In either case above do NOT allow the bellows to be exposed

to the cold any longer five minutes because you can damage this very

expensive piece.

Return to Index

Replacement

The bellows or "motor" contains the following:

1) Motor knobs (either two or four nuts); Part # 3519.

2) Motor protection plate; Part # 3546.

3) Coil spring (70mm); Part # 3547

4) Metal (brass) drum; Part # 3580

5) Bellows; Part # 3581

6) Drum cover; Part # 3582

For schematics with the part numbers, please see:

Part Schematics

In order to replace the old bellows for a new one you first

remove the entire "motor" or bellows chamber (see above). There

are either two or four brass nuts which hold the motor to the back

of the frame plate. I use a 5/16" closed end wrench to remove these

nuts. A word of warning here because the above mentioned chain

is attached to a fairly strong spring and that spring will "push" the

bellows chamber away from the movement as you remove these

nuts. On the caliber (model) # 540 the bellows chamber is removed

by exerting a counter-clockwise (bayonet fitting) turning pressure

with your hands and be sure to turn the "inner" part of the

drum. In other words turn as close to the frame as possible.

To remove the old bellows you must make sure it is fully

compressed. An old bellows with all of its gas leaked away will

measure about 40 mm from the top of the metal drum to the top of

the compressed bellows. Most usually have some gas (ethylene chloride)

remaining. Therefore you must compress the bellows yourself. Some

place the chamber into the refrigerator but I like to use ice cubes.

Usually one ice cube is enough to fully compress the bellows in about

a minute. Once it is compressed, push down on the drum cover

(part # 3582) to loosen any bonds that may have formed on that cover

and the coil spring (part # 3547).

On the caliber 540, once the bellows chamber is removed from

the frame, the bellows casing has a bayonet fixing in which both halves

must be turned in opposite directions, with the back of the drum moving

counter-clockwise. Use an ice cube to collapse the bellows when both

removing and installing.

Once satisfied that the coil spring is "flexible" then push down

on the drum cover and turn it in either direction until the four (4) tabs

are fully exposed from under the four (4) tabs which are located on the

metal drum. Caution should be used because of the tension in the coil

spring. This tension will make the drum and the cover separate rapidly

unless you supply the "containing" force so they do not spring

apart quickly.

The rest should be common sense and you do exactly the

opposite in order to place the new bellows inside the motor starting

with the ice cube.

Return to Index

Suppliers of Atmos Parts

The following is a Web site that describes all of the Atmos parts that

I sell. I sell virtually every part for the LeCoultre Atmos.

Obtaining Atmos Parts

Return to Index

Manual Winding

There are several ways to manually wind the Atmos. By far the

best way is to remove the metal drum (part # 3580) which contains the

bellows (part # 3581). The metal drum, which some incorrectly refer to as the

bellows, is simply removed from the frame in order to access the coil spring.

Once it is removed you will see a coil spring (part # 3494) with a brass chain

(part # 3491) running through the middle and attached to the end of the chain

with an aluminum cap called the spring guide (part # 3493). This is all held

together by a bent steel straight pin called the chain stopper (part # 3492).

In order to wind the mainspring properly you simply become the

bellows. Push the coil spring in toward the movement until it will not

compress any more. Then remove you hand and the coil spring will

try to go back to its original position. This going back to the original

position is the actually winding taking place.

By pushing in the coil spring, the clock "prepares" for the

eventually going back or winding. This is similar to a pocket watch

where one direction actually winds the watch and the opposite direction

allows you to go back to the previous position to wind it again.

The reason I like to use the above method is because the

combination of the coil spring and the bridled mainspring does NOT

allow for over winding, assuming you do not "help" the coil

spring while it springs back and you stop pushing when the coil spring's

extension is slightly less than it did the time before. So once you have

compressed the coil spring and it does not "recoil" back to the

original position, the clock is fully wound.

A fully wound clock should run for about 14 months, with about

7 or 8 of those months having enough power to run accurately. After

that the time keeping tends to deteriorate.

If the Atmos still does not run after manual winding, please be

sure to tell the person you are going to hire to overhaul the clock. The

reason is that a marginal bellows will probably not be refilled if the

repair person counts a "healthy" wind on the mainspring.

If wound properly, either by the bellows or by hand

(removing the bellows and pushing the coil spring), which was

described above, then the amount of running time totally depends

on the caliber.

All of these will vary by as much as 4 months but a

caliber 540 will run anywhere from 10 months to 14 months.

A caliber 528/526 will run anywhere from 14 to 16 months and

a caliber 519 and the Atmos II will run anywhere from 15 months

to 2 years.

All of this has to do with the quality and length of

the mainspring. And of course the actual condition of the

movement and frame will change these numbers.

Some choose to wind by turning the chain and spring pulley

(part # 3486). That method is not controllable and you can wind

it too little or too much.

Too little will not hurt anything but too much and

then the clock can have too much power and the balance may

over swing causing the clock to run fast because the roller

will hit the fork on the opposite side and that will limit

the "natural" swing. The general clock terms this is called

over swing.

Another danger of winding this way is that the "stopping

pin" that secures the chain to the "chain stopper", which is the

cap of the coil spring, may become dislodged and the chain will

eventually lose its tension and if the bellows still has some

gas left, then there is no way it will wind the clock.

So please don't be lazy and try to wind by pushing the chain and spring

pulley. I'm mentioning this because some on the Internet advise winding this

way and it's an accident waiting to happen.

Return to Index

Refilling Atmos Bellows

If you want the bellows refilled as a stand alone service, then

the cost is $470.00. That includes return shipping (in the U.S.) and

you will have to remove the spent bellows and sent it to me and

reinstall the refilled bellows.

Refilled bellows carry a 2-year warranty. It's about 4 weeks from the

time I receive your check made out to Mike Murray for $470.00 in the US.

The shipping charge is $20.00 to the US, $45.00 to Canada and

$65.00 to the rest of the world, which includes insurance. For one

week shipping to the rest of the world, you may add $80.00 to the

total of the order because the $65.00 option takes about 2 weeks.

The final price outside North America is either $515.00 or $530.00

depending on your shipping choice.

Please be aware that I do not perform the service myself and

send out the bellows for refilling. Therefore, you must allow

about six weeks for the service and the possibility that the refill

failed.

If you do not have the old bellows, then I can supply a bellows

usually manufactured within a few years of your serial #. That adds

$150.00 to the $450.00 mentioned above.

You must be aware that there is a 20% failure on refilling used

bellows. Therefore, I cannot guarantee that your bellows refill will

be successful. I can, however, have one of my old stock bellows refilled

in case of failure and that adds $150.00 to the refilling charge (see below).

If the procedure fails, then I'll return your original bellows

at no charge, assuming that you sent just the bellows for refilling or

take a spend bellows from my inventory that is close to the date of

your original bellows (usually within a year) and charge $150.00 extra

for a total of $620.00 and that includes the used bellows from my

inventory.

If you sent the entire clock as part of an overhaul, then I will

install either a new bellows at an extra cost of $900.00 (price subject to change)

or use another refilled bellows that is close to the date of your original bellows

(usually within a year) for the an extra $150.00 for a total cost of $600.00.

I would like payment by money order, certified check, personal check,

business check, or through Pay Pal or Square, which is the only way I take

credit cards. I do prefer a check over a credit card because Pay Pal and Square

take 3%. I only take credit cards if you are in the USA or Canada.

The 3% is added to the total bill if you use a credit card.

With either Pay Pal or Square, I will send an invoice to your E-mail

address. Here you are dealing directly with either service and not me

and you do not have to be a member of either.

All of the added fees are exactly what either service charges me

for taking your credit card.

Return to Index

Replacing Soldered Bellows

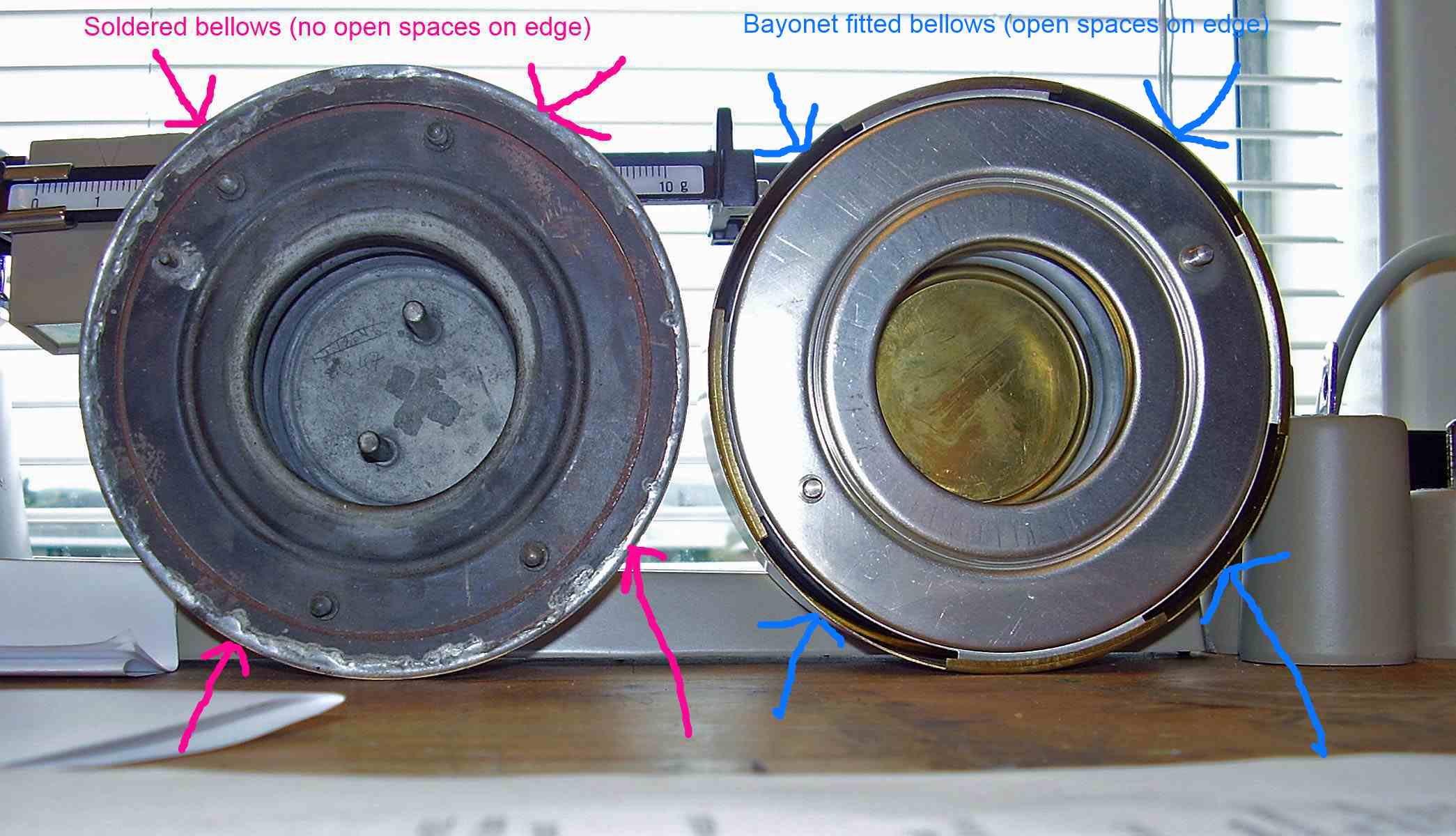

The bellows on the left are soldered and the bellows on the right are the

bayonet fitted bellows which can easily be removed if refilling is indicated.

If you look real close at the soldered bellows on the left, you will see that

they have already been cut and the pains taking task of removing the old bellows

has yet to begin.

I have a file for replacing the older soldered bellows without having

to desolder. It's located at Bellows2.pdf an Acrobat file.

If you want your soldered bellows replaced with a new bellows as a stand alone

service, then the cost is $2,500.00. That includes return shipping (in the U.S.)

and you will have to remove the entire bellows (cover and motor included) and sent

it to me and reinstall the completed bellows. At least 1/2 of the $2,500.00 ($1,250.00)

must be pre paid and the service can take as long as 3 months because of slowness in

the ordering process for the new bellows.

The bellows on the left are soldered and the bellows on the right are the

bayonet fitted bellows which can easily be removed if refilling is indicated.

If you look real close at the soldered bellows on the left, you will see that

they have already been cut and the pains taking task of removing the old bellows

has yet to begin.

I have a file for replacing the older soldered bellows without having

to desolder. It's located at Bellows2.pdf an Acrobat file.

If you want your soldered bellows replaced with a new bellows as a stand alone

service, then the cost is $2,500.00. That includes return shipping (in the U.S.)

and you will have to remove the entire bellows (cover and motor included) and sent

it to me and reinstall the completed bellows. At least 1/2 of the $2,500.00 ($1,250.00)

must be pre paid and the service can take as long as 3 months because of slowness in

the ordering process for the new bellows.

For dealing with soldered bellows as part of the Atmos clock overhaul service,

please see this link: Soldered Bellows as part of an overhaul

Return to Index

A service from, E-mail address: Mike@atmosclock.us

Mike Murray Founder of Clocksmiths

A specialist in Atmos and 400-day clock repair.

Also, I overhaul most plug in electric clocks.

In continuous service since 04/01/1982.

Mike's Clock Clinic Memberships: Clocksmiths & NAWCC

P. O. Box 562 1151 D Street Fossil, OR 97830-0562

My Web site is located at http://www.atmosclock.us/

Main FTP site is located at http://www.atmosman.com/earthpdf.html

Memberships: Clocksmiths & NAWCC

N.A.W.C.C. International 400-day Clock Chapter # 168

Published in Chapter 168's "Torsion Times"

Published in AWCI's "Horological Times"

Formally AWCI's 400-day (Anniversary) clock Bench Course Instructor!